A milling machine is the best tool for cutting metals to the customized dimensions and shapes especially if the parts are to be cut or shaped to rectangular or uneven dimensions. Two types of milling devices are employed in workshops manual and CNC milling. High Power Metal Mini Lathe DIY Micro Milling Machine Mill 12000rpm 60W with Adapter. 3.0 out of 5 stars 2.

- Milling Machine Operation Video

- Small Home Milling Machine

- Milling Machine Demothe Mechanic

- Milling Machine Demo The Mechanical

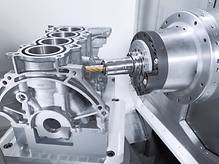

At Dan's Machine Tool, Inc., we specialize in the repair and reconditioning of all types of metalworking equipment. Customers trust us to provide the critical repairs to their mills, lathes, iron workers, benders, and other machinery that keep production running. When a piece of equipment is down or not functioning properly, an experienced technician can make a visit to the customer’s facility in order to make an initial diagnosis. Depending on the severity of the issue, a repair may be made on-site or the equipment can be transferred to our facility.

For full rebuilds, equipment is cleaned, disassembled, and all components are evaluated for wear. Any belts, bushings, fasteners, and other wear parts are replaced as needed and structural repairs are completed to the frame and body. Ways can be ground parallel and hand scraped to factory tolerances. The machine can then be reassembled and tested to customer requirements. We can also repair and rebuild older equipment that most shops no longer support, including Bridgeport mills. Through our extensive used equipment network, we maintain a significant inventory of hard to find replacement parts salvaged from older machinery. For more information about our equipment repair and rebuilding capability, see the table below, or contact us directly.

Photo Gallery of Before & After Repairs & Rebuilds

- Lathe/milling machine operators at KUKA convert a raw piece of metal into a high-precision component. Time and time again, they check whether each workpiece is exactly as it should be. As a result, even during your apprenticeship as lathe/milling machine operator at KUKA, you will learn everything about inspection and test processes and equipment.

- The planner milling machine is mostly used for facing operations in mass production. These machines are similar to the bed type mill machine, except it can be mounted with various cutters and spindle heads to the machine. These cutters in the machines can perform the facing operations simultaneously which is a great function. Special milling.

LeBlond Lathe Rebuild

(click on thumbnail to enlarge)

Mori Seiki Lathe Repair & Rebuild

(click on thumbnail to enlarge)

Bridgeport Milling Machine Repair & Rebuild

(click on thumbnail to enlarge)

Project Showcase of Metalworking Equipment Repair & Rebuilds

Machines & Brands We Repair

- Milling Machines

- Acra

Bridgeport

Cincinnati

Clark - Kent

Jet

Lagun

All import milling machines

- Acra

- Lathes

- Acra

Clark

Cadillac

Hardinge - Kent

Mori Seiki

LeBlond

Webb

All imported lathes

- Acra

- Surface Grinders

- Boyar Schultz

Harig

Kent - Mitsui

All imports

- Boyar Schultz

Metalworking Equipment Repair & Rebuilding Capabilities

- Capabilities

- Repair

Rebuilding - Maintenance Agreements

Replacement Part Supply

- Repair

- Equipment Types Available

- Mills

Lathes

Grinders

Saws

Shears - Iron Workers

Benders

Rolling Equipment

Routers

Presses

- Mills

- Repair & Rebuilding Processes

- Complete Rebuild

Head Repair

Spindle Rebuilding - Scraping of Ways

Table Resurfacing

- Complete Rebuild

- Brands

- JET Machinery

Acra

Scotchman - Ercolina

Chevalier

Majestic

- JET Machinery

- Automation

- Manual

CNC

- Additional Services

- Repair

Replacement Parts

Used Equipment Purchasing

- Lead Time

- Quoted on a Job by Job Basis

- Industries Served

- Metalworking

Manufacturing

Fabrication Shops

Dan’s Machine Tool, Inc. offers Preventative Maintenance and Diagnostic Inspection for CNC and Manual Machinery:

MILLING MACHINES, GRINDERS, LATHES, BANDSAWS, DRILL PRESSES, PUNCH PRESSES, SHEAR AND BRAKES, ETC.

Our Preventative Maintenance can be performed Economically to Prevent equipment Breakdowns before they occur and notify you of potential Safety Issues!

The Maintenance and Diagnostic Inspection consist of multiple key steps that help prevent premature wear to vital components on your machinery. Our Diagnostic Inspection lets you know if your machinery is operating to Factory Tolerances and its full potential.

Our Preventative Maintenance and Diagnostic Inspection consist of:

Testing Axes, Spindles, Chucks, Tailstock, Leadscrews, Ball Screws and Bed Ways for excessive run out and backlash.

Ensure lubrication and hydraulic systems are dispensing properly. Draining and refilling lubrication and hydraulic reservoirs with new Grease, Way Lube and or Hydraulic Fluids. Also check the old lubrications for contaminants!

Run machinery to ensure all feeds, gears, motors and spindles etc. are operating freely and properly.

Check all electrical components, machinery conduit, on off switches, emergency switches and electrical cabinets to ensure operators safety!

During maintenance our mechanics will adjust gibs, lubrication fittings, handles, loose conduit and electrical connections. Also removing debris, excess grease and lubrication from the body and operating areas of the machinery.

Providing a complete diagnostic report to your company detailing findings.

PURCHASE ORDER REQUIRED, PLEASE CALL TO SCHEDULE

Milling Machine Operation Video

OUR TERMS: NET ON COMPLETION

For over 34 years, Billor McDowell has been an industry leader in CNC Machine repair. With expert technicians, we service all makes and models of CNC machine tools.

Experienced Experts

Our expert mechanics average over 25 years of experience working on all makes and models of CNC machinery.

Small Home Milling Machine

Repair & Maintenance Services

From emergency repairs to preventative maintenance, we do it all.

We take great pride in providing best in class service, while remaining cost effective for our customers. Our success is based on a record of integrity and trust with a primary goal of building long-term customer relationships. Give us a quick call to discuss your requirements, or to schedule service.

Quality Products

Milling Machine Demothe Mechanic

Milling Machine Demo The Mechanical

We offer a number of machine tool, saw, & fabrication lines to meet your metal cutting needs. In addition to new machinery we offer used parts & machinery. Please visit our EBay store for a current list of used parts and machinery. We have a robust stock room and offer aftermarket parts support for all machine tool lines.